Construction Lessons from Mars

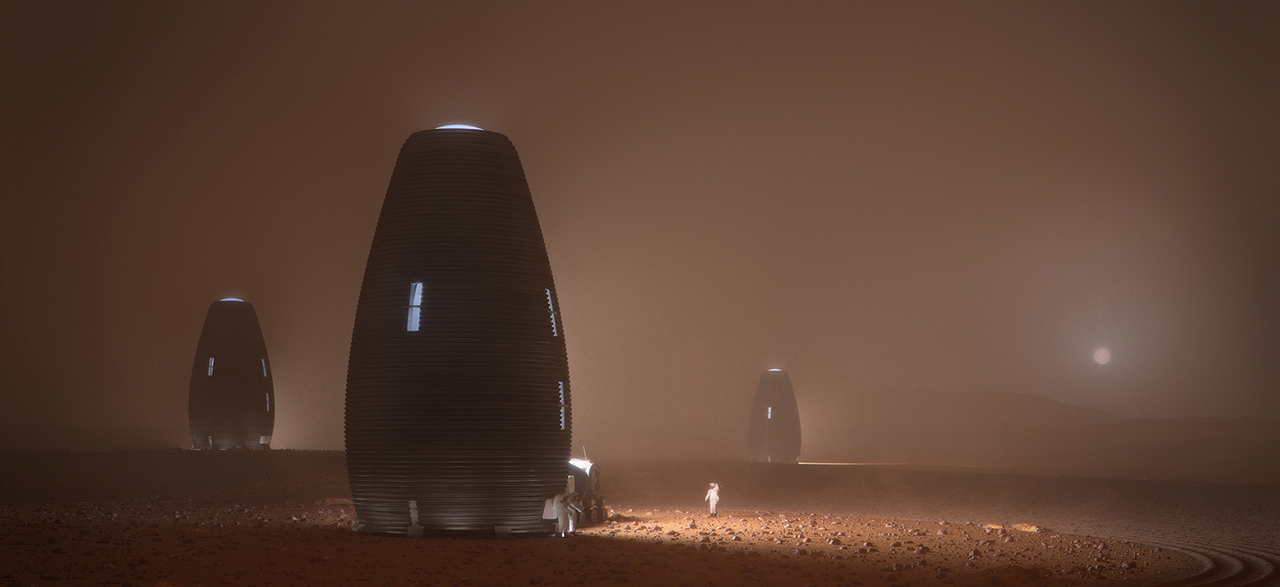

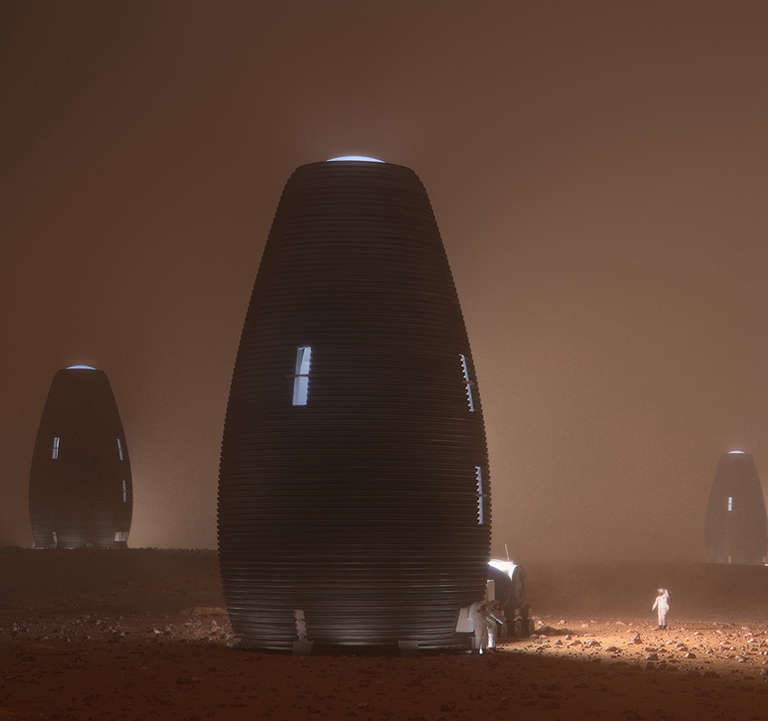

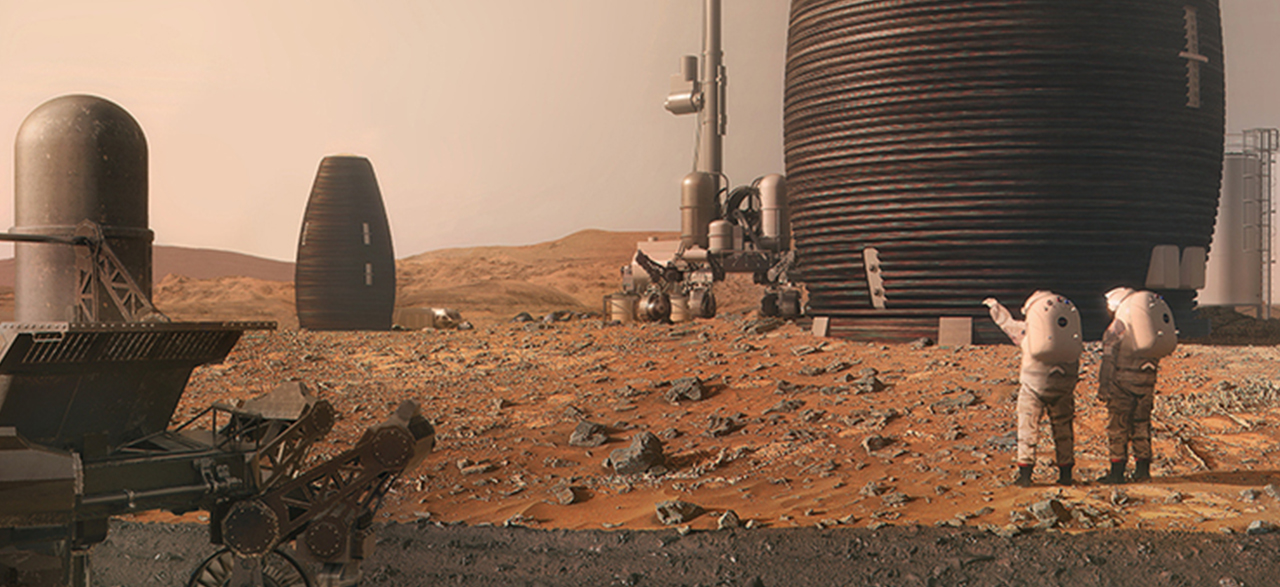

The winner of the NASA Centennial Challenge, AI SpaceFactory’s MARSHA habitat is designed to utilise in-situ construction methods to create habitable structures on Mars. But its approach could provide construction benefits far closer to home

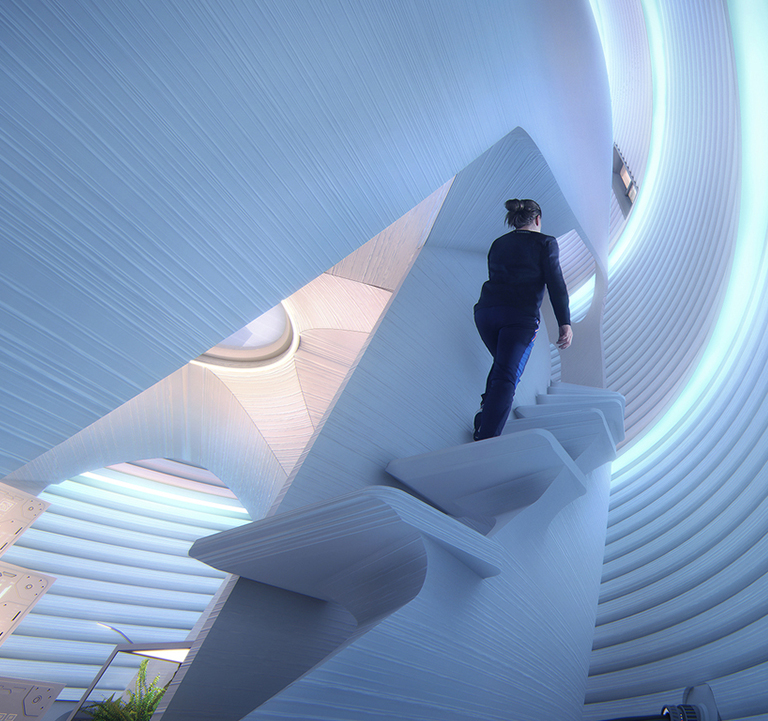

As the winner of the NASA Centennial Challenge, MARSHA is challenging conventional thought about space habitat design, creating a multi-storey structure that is light and airy.

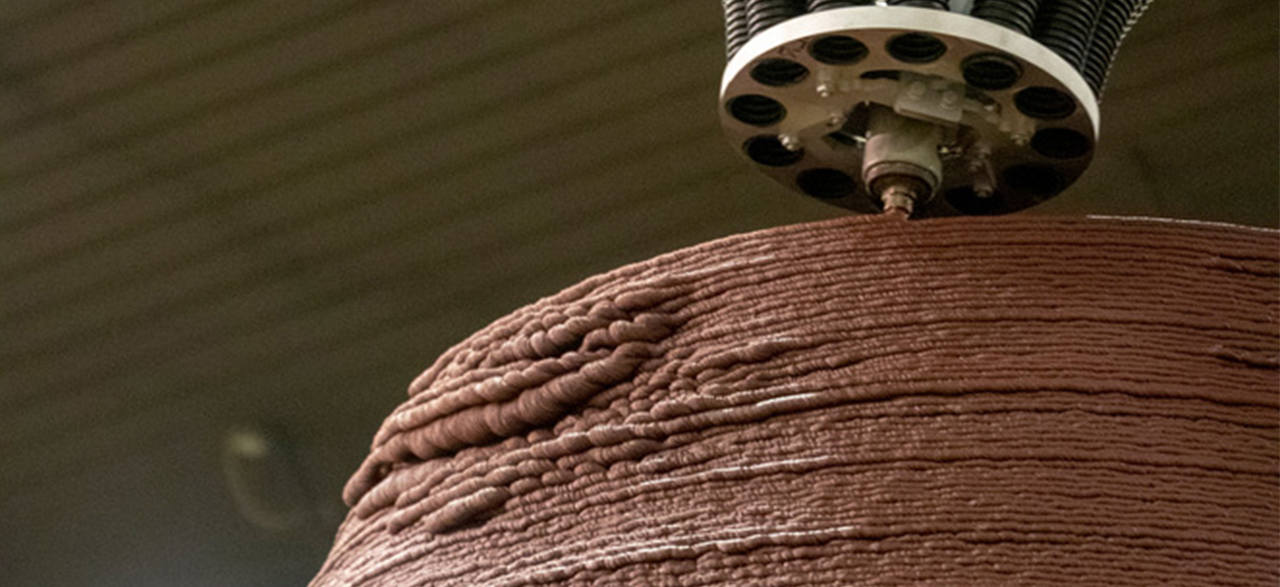

Designed to be 3D printed using a material made on Mars, it is built from a novel combination of basalt fiber and renewable bioplastic, which has proved to be far stronger and more durable than concrete alternatives.

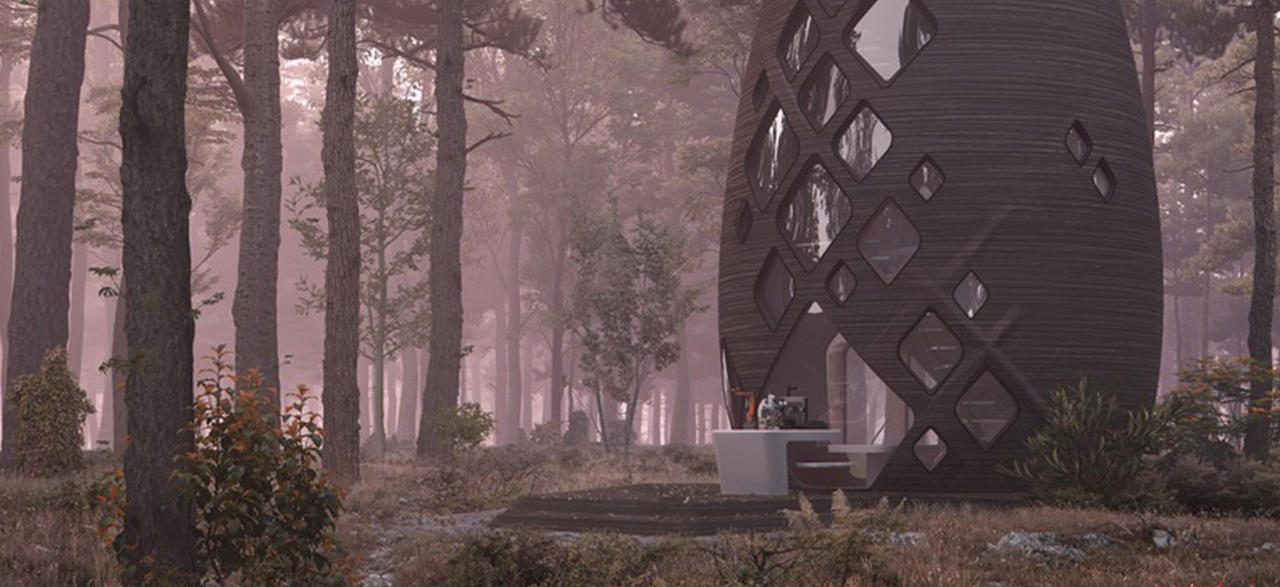

The material could, therefore, also prove to be a valuable concrete alternative on Earth, a vision that will be demonstrated with the construction of TERA, an Earth-based version of the habitat that AI SpaceFactory plans to build.

“We developed these technologies for Space, but they have the potential to transform the way we build on Earth,” said David Malott, CEO and founder of AI SpaceFactory. “By using natural, biodegradable materials grown from crops, we could eliminate the building industry’s massive waste of unrecyclable concrete and restore our planet.

Positioned as a futuristic eco-habitat, TERA will be designed to be more ephemeral than conventional buildings, with the ability to be composted back into the soil at the end of its lifecycle.

“In building TERA, we are doing more than proving out a technology,” said Malott. “We are sending out a message to the building industry that there is another way. Building with concrete may be tried and true, but that does not make it right.”

As the winner of the NASA Centennial Challenge, MARSHA is challenging conventional thought about space habitat design, creating a multi-storey structure that is light and airy.

Designed to be 3D printed using a material made on Mars, it is built from a novel combination of basalt fiber and renewable bioplastic, which has proved to be far stronger and more durable than concrete alternatives.

The material could, therefore, also prove to be a valuable concrete alternative on Earth, a vision that will be demonstrated with the construction of TERA, an Earth-based version of the habitat that AI SpaceFactory plans to build.

“We developed these technologies for Space, but they have the potential to transform the way we build on Earth,” said David Malott, CEO and founder of AI SpaceFactory. “By using natural, biodegradable materials grown from crops, we could eliminate the building industry’s massive waste of unrecyclable concrete and restore our planet.

Positioned as a futuristic eco-habitat, TERA will be designed to be more ephemeral than conventional buildings, with the ability to be composted back into the soil at the end of its lifecycle.