INNOVATIVE AND COSMOPOLITAN

CaPlast has specialised in various high-grade substrate coatings since 1967. Part of the KAP Beteiligungs-AG, CaPlast has strong financial assets as well as market-based and application related expertise which is well known around the world. This guarantees the constant development of our high-tech systems as well as proximity to our clients.

Modern systems for extrusion coatings and laminating systems enable various substrates to be combined with one another or to be provided with a coating. Specially coordinated pre-treatment methods prepare the substrates for optimum adhesion. Internally, we have developed this technology further and as such, we lead the way when it comes to the future and the challenges which the development and production of technically high quality products throws up.

Environmentally-friendly production techniques, solvent-free / plasticiser-free products and the latest in finishings allow us to process customer specific parameters without compromising quality. The highly developed manufacturing technology and specific expertise in terms of the wide ranging product applications add up to make CaPlast a specialist for bespoke products in the field of coatings.

The core activities range from a broad product line for the construction sector to niche products for automobiles. Through a clear strategy and constant training, we live up to our claim of demonstrating our ability as an innovative specialist for bespoke products in the field of coatings every day.

Quality, safety and sustainability are top priorities. Therefore, the quality and energy management system (DIN EN ISO 9001 and DIN EN ISO 50001) ensure a constant review and improvement of the processes.

Scroll down

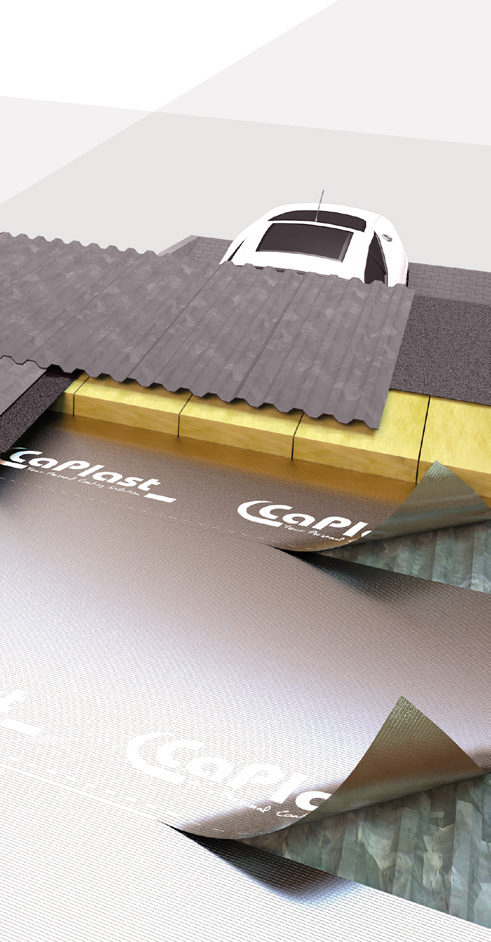

The CaPlast world of roofing products

Click | tap on the images

New standards, rules and data sheets – the world continues to turn despite the economic crisis. Understanding the ‘crisis as an opportunity’ is an ever popular phrase – even if few opportunities can be recognized. The CaPlast team have recognized the opportunities for trade, roofers and carpenters and here, in one full swing, are happy to present their new products.

A highlight: the new CaTop UD 300, a weldable PU underlay roofing strip for creating watertight underroof. Following the slogan: “easier, more functional, cheaper and quicker to work with”, we have succeeded in creating unique lightweight, cold-weldable and hot weldable underlay roofing strip which is open to diffusion.

We have launched new products in the field of vapour barriers / vapour traps as well. With CaVap SK 1500, a full surface, self-adhesive flat roof vapor barrier is now available that, in addition to its technical values, satisfies the user through the secure and time-saving way in which the laying takes place. With the new CaVap 2, the future demands for greater surface tension have already been implemented today. The result is a product that is flexible, can be processed everywhere and has excellent adhesive properties, even in the most adverse climatic conditions.

Together with the CaPlast team, we invite you to make use of today’s opportunities and those the future. Try us out!

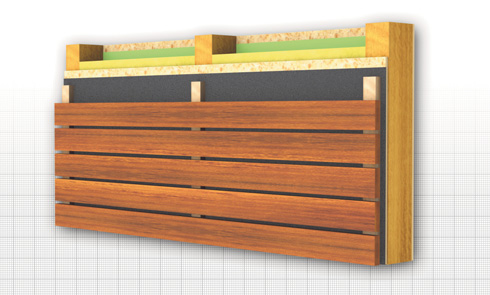

CaWrap Facade Membrane

Especially conceived for the market based on modernisation materials, the facade cladding made of curtained back-vented facades with wood or stone and the open joints that result (as a design element) is gaining ground.

The fulfillment of the resulting requirements for water tightness, UV-stability and high anti-tear values is best secured with CaWrap UV 200. The PU-coated monolithic-coated facade has a long-term UV protection lasting 10 years.

As such, it guarantees all technical characteristics. It is also very easy to handle and has almost no impact on the supporting structure.

The widths (of up to 300 cm) as well as the integrated self-adhesion also ensure economic processing as well as the highest quality standards.

Fire resistant vapour barrier

that offers an outdoor weathering capacity of 6 to 8 weeks

CaPlast introduced the cold self-adhesive, fire and penetration-resistant CaVap Alu 1500 SK vapour barrier six years ago. At the time full-surface self-adhesive material across the entire membrane was an innovation. It made the precise installation of vapour barriers on extensive trapezoid sheet roofs simpler and more convenient. Now CaPlast is presenting its latest generation of products with improved outdoor weathering capacities.

General Manager Frederik Schaefer: „Of course, the aluminium composite foil CaVAP Alu 1500 SK still offers top quality performance with its outstanding diffusion resistance, but in addition scores with an outdoor weathering capacity of six to eight weeks. This offers the installation companies much more flexibility if they are faced by any delays. “

CaFloor:

System solutions under tiles and floor coverings

An extended accessories range in combination with the continuous testing of innovative layer structures has paid off: We register an increasing demand for customised system solutions in the field of sealing membranes for tiles, panels and mosaics. Visitors can take a look behind the scenes at our development processes at the BAU 2019 trade fair. We will be presenting a fully self-adhesive sealing sheet under tiles and panels that will be ready for a market launch next year. The advantage: Tile adhesive for wall and floor installation as well as the accompanying working steps can be dispensed with.

In addition, we have reorganised and expanded the structure of the CaFloor product segment comprising of sealing membranes, decoupling membranes as well as moisture and radon barriers. “The CaFloor products are optimised for the requirements of different substrates, wall and floor coverings in terms of their waterproofness, flexibility, alkali resistance and perforation resistance. By means of this reorientation, we are emphasising the advantages of the respective products even more clearly and are transforming individual product solutions into a reliable, integrated system,” explains Key Account Manager Pierre-René Linne.

On the way to the closed-loop economy

In 2015, the European Commission launched an action plan designed to accelerate Europe‘s transition to a closed-loop economy. As a responsible company we look forwards to accomplishing this major macroeconomic task with confidence.

All the companies in the plastics processing industry agree on one point: our industry plays a key role in ensuring the transformation from a linear economy to a sustainable closed-loop economy. We still have to perform a large amount of research and work persuading people. However, innovations in the development of new biopolymers and advanced environmental technology are already making a lot of things possible, and numerous sustainability projects have thus also been initiated at CaPlast.

The use of natural resources

Cellulose, sugar cane, molasses, starch, vegetable oils, but also wood fibres and flax, are currently the most commonly used raw materials for the production of bio-based biopolymers. At CaPlast, we are keenly observing the further developments in terms of processing behaviour, functionality and degradability and have already tested the first materials in relation to their suitability for coating at our technical centre. That‘s because one thing goes without saying: bio-based materials also have to demonstrate outstanding results in terms of their UV stability, fire behaviour, longevity and recyclability.

Biopolymers as the focal point of our development work

- Biodegradable bioplastics from fossil fuels

- Compostable and / or biodegradable bioplastics derived from renewable raw materials of animal and plant origin and also from microorganism synthesis

CaPlast’s sustainability goals at a glance

- Further development of recyclability towards the sorted recycling of homogeneous materials

- Sustainability throughout the entire value-added chain

- Absence of pollutants

- Use of compostable and / or degradable biopolymers

You would like to know more about the potential applications of biopolymers for technical textiles? Simply talk to us!

Caplast Kunststoffverarbeitungs GmbH Sales, +49 2599 9130

Contact

CaPlast Kunststoffverarbeitungs GmbH

Magdheide 7

DE-59394 Nordkirchen

Phone: +49 (0) 2599/91 3-0

Email: info@caplast.de

Web: www.caplast.de