The Future of Robotic Construction: A Solution to the Industry’s Most Pressing Issues?

The construction industry is increasingly exploring the use of robots to speed up work and alleviate skills shortages. But where could this lead? Luke Christou explores the future of robotic construction

Where we are with construction robotics “doesn’t have an easy answer”, Borja Garcia de Soto, assistant professor of Civil and Urban Engineering at NYU Abu Dhabi & director of the S.M.A.R.T. Construction Research group, says.

If we consider robots “an autonomous system which exists in the physical world, can sense its environment, and can act on it to achieve some goals”, as defined by Dr. Maja Matarić, author of The Robotics Primer, then the construction industry “still struggles to pass the prototype and research stages”.

However, the use of single-task robots (STR) in the construction industry has been growing for some time. "Robots are now commonly used in processes such as manufacturing, as well as inspection and monitoring,” Mark Ireland, chief engineer, Technology Strategy, for the Manufacturing Technology Centre (MTC), explains.

“When you consider the full scope of robotics and automation there is a lot of work currently underway, specifically around automation of design and the use of industrial automation in the manufacture of sub-assemblies off site.

“There is also a lot of work on robotics and automation for the infrastructure sector, helping to complete difficult, time intensive tasks which would normally need to be completed manually. This includes everything from drones for surveying, pipe inspection and underwater inspection.”

Various ideas, prototypes and early applications continue to demonstrate where robots can aid in the construction process. And as researchers, academics, and technology companies continue to push the boundaries, the role that robots play in construction is set to grow.

Driving the second wave of robotic construction

The use of robotics in construction dates back to 1970s Japan. As young workers turned their back on manual labour in favour of less dangerous and physically demanding office jobs, Japan’s largest architecture, engineering and construction companies turned to automation and robotics in an attempt to stem a labour shortage.

Many of these technologies failed to break ground, and construction’s labour issue persists. According to Turner and Townsend’s 2019 International Construction Market survey, 66% of construction markets globally report a shortage of skills.

This decline is set to continue with the rate of retirement also on the up. In the United Kingdom, for example, where construction companies have reported a shortage in every region excluding Scotland, 15% of the construction workforce is aged over 60. A further 7% of the workforce are aged in their 50s.

“ There is a huge demand and backlog of construction work that can’t BE built — think roads, solar and wind farms, energy pipelines, levees, and homes. ”

“There is a huge demand and backlog of construction work that can’t be built — think roads, solar and wind farms, energy pipelines, levees and homes — because we don’t have enough skilled workers entering construction,” Erol Ahmed, director of communications for Built Robotics, explains.

Companies such as Built Robotics are developing solutions to solve the labour crisis. The construction robotics company has developed an AI guidance system that can be fitted to heavy equipment, enabling it to operate autonomously and reducing the need for human workers.

Labour shortages is just one of many issues that the construction industry faces, however. Lacking worker safety is another pressing issue, with construction the leading industry for workplace fatalities in many parts of the world. Construction waste, and its environmental impact, is also on the list.

Robotics: A solution to construction’s most pressing issues

Modern technology can provide a way to tackle these problems and the construction industry is looking to technology, robotics included, to provide the answers.

“Some of the most relevant technology currently available includes mobile and cloud computing/telecommunications, 5G, big data and deep learning, wireless sensor networks, machine vision, autonomous vehicles and Building Information Modelling (BIM). Besides, the push of data analytics driven by advances in artificial intelligence (AI) is becoming a game-changer,” Garcia de Soto says.

“The status quo is a significant factor, but many contractors are starting to realise the benefits of automation and the use of robotic systems on their projects.”

“ The status quo is a significant factor, but many contractors are starting to realise the benefits of automation and the use of robotic systems on their projects. ”

Stuart Maggs, CEO of Scaled Robotics, which develops automated robots capable of monitoring progress and build quality, shares this view. This improved understanding is evident from the number of companies seeking out innovative solutions, such as those offered by Scaled Robotics.

“The construction industry as a whole is looking for new solutions and we have definitely seen an uptick in companies actively approaching us for our technology,” Maggs says.

“The really big shift we have seen is in the maturity of their digital workflows and the understanding of how technologies like ours can really be implemented successfully.”

Robotic construction: A roadmap to 2030

There are issues to be solved and an interest in solving them, but how likely are we to see construction sites buzzing with autonomous bots in the next decade, and what jobs are they likely to take on?

“I do not have a crystal ball,” Garcia de Soto insists. However, his research at NYU Abu Dhabi has provided him with insight into where automation can be best applied throughout the various phases of a construction project.

“Being optimistic and based on the current developments that we see from the research community, the technological advancements, and the recent interests by contractors, I would expect that, within the next decade, we will start to see significant advancements in the use of robots during the construction and O&M [operations & maintenance] phases,” Garcia de Soto says.

The industry seems largely in agreement that these significant advancements will first focus on removing humans from dangerous tasks. Automation is also likely to take over the tedious tasks, freeing up time for labourers to complete more fulfilling work.

“The tasks that are the most dangerous, most repetitive, or most remote are the tasks likely to become automated to keep construction workers safer and allow them to focus on more complex and skilled labour,” Ahmed states.

“ I would expect that, within the next decade, we will start to see significant advancements in the use of robots during the construction and O&M phases. ”

According to Garcia de Soto, the tunneling and mining industries offer a good indication of where construction will head. These industries are already reliant on robotics for excavation, dozing, drilling and explosive handling among other risky tasks.

However, further research and innovation is needed before robots are ready to go beyond data capture or simple finishing jobs, and begin carrying out physical construction tasks.

“Currently, we are using robots predominantly to automate the capture of data which can then be used to analyse the construction process,” Maggs explains.

“The really interesting and most challenging change will be when we move from pushing data from the physical world into digital platforms and start taking data from the digital world and putting it into the physical world to automating construction tasks.”

Testing the boundaries of construction

The TyBot rebar tying robot and Construction Robotics’ bricklaying robot SAM and lift assistance device MULE, pictured, are good examples of how robots can help out on construction sites. Yet, these systems, while useful for automating the more tedious elements of construction, offer little more than what human workers do already.

According to Maggs, the industry needs to look beyond mimicking human capabilities and exploring the possibilities of what robots can offer that humans can’t.

“ The end goal has to be not just automating tasks that human beings can do, but developing new construction manufacturing methods that are only possible through robotics. ”

“Pushing further on from these first examples, the end goal has to be not just automating tasks that human beings can do, but developing new construction manufacturing methods that are only possible through robotics, opening up new possibilities for building design and performance,” Maggs says.

MIT’s recent FIBERBOTS project, which can be viewed below, offers a good example of how robots can be deployed to perform construction tasks that humans would find difficult to copy. A ‘swarm’ of 16 autonomous robots were developed and deployed to create tubular structures by winding fibreglass filament around themselves.

Rather than humans, FIBERBOTS mimic the behaviours of insects such as spiders and ants, and are able to tune the material make-up of their structures at will based on environmental cues.

A lack of agreement

Giving its early applications, and the progress that is being made, it is widely accepted that robotics will play a role in the future of construction. However, views differ on exactly what that role is.

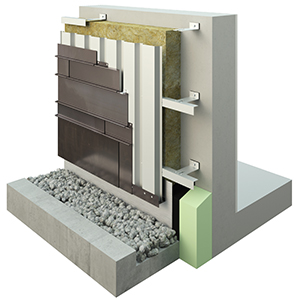

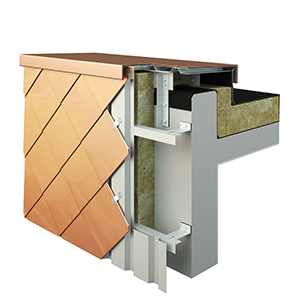

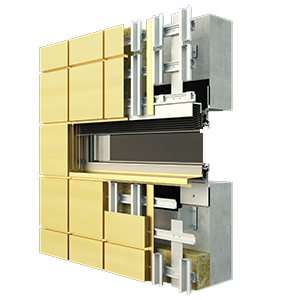

“It is almost inevitable that robotics and automation will become commonplace in factories off site, being used to manufacture panels, volumetric modules and sub-assemblies, but it is unlikely that they will appear on-site any time soon,” Ireland says.

Automation is an answer to many complexities in the construction process. However, Ireland suggests that it isn’t necessarily the answer to every problem. In fact, many of these problems could be “designed out” of the construction process altogether, removing the need for costly automation.

“ It is almost inevitable that robotics and automation will become commonplace in factories off site. ”

Ireland points to reinforcing bar (rebar) as an example of where automation is being applied incorrectly:

“A large amount of work has been completed looking at how rebar can be automatically tied, but if rebar could be removed through the use of composite fibres, steel reinforcing staples, or through the use of an alternative approach such as screw piles, then the need for automation goes away.”

This lack of agreement goes beyond those researching, developing and testing solutions. According to KPMG’s Global Construction Survey 2019, construction firms are also undecided.

While over half of the top 20% of firms embracing technology believe that AI will be commonplace in construction within the next five years, that figure drops to just under a third for the other 80% of firms.

Robotic construction brings new challenges

Robotic construction offers to solve many challenges in the industry, but its implementation will undoubtedly present new ones over the next decade too.

Given the economic benefits it offers, such as improved build speed, productivity and quality, robotic construction seems to make good business sense. However, it also raises questions regarding ownership, maintenance, cost and so on.

“The challenge around using cutting edge technologies is that they still need a lot of development and business cases are not fully understood. Who will own them? maintain them? program them? what is the business case for a large fleet of capitally expensive equipment?” Ireland questions.

Capital is likely to pose a problem too. Contractors will need to front the cost to deploy and finetune these systems before they start to see any economic benefit.

“ The challenge around using cutting edge technologies is that they still need a lot of development and business cases are not fully understood. ”

Cybersecurity presents another challenge that could hold robotic construction back.

In 2017, cybercriminals launched an attack on a Saudi Arabian oil refinery with the intent of disabling security systems and triggering an explosion. It isn’t much of a stretch to envision construction robots being manipulated in a similar fashion to cause destruction.

Garcia de Soto’s team of researchers, in collaboration with the Center for Cyber Security at NYU Abu Dhabi, are exploring cybersecurity in the construction industry, aimed at identifying why the industry might be a target for cybercriminals, how such attacks are likely to be carried out, what the impact would be, and how to defend against them.

“Making sure that it is safe (from a cybersecurity point of view) to use robotic systems and new technologies in the construction sector will be key to getting the trust from different stakeholders and facilitate the deployment of such systems at a larger scale,” Garcia de Soto believes.

Can robotic construction overcome these challenges? There are still plenty of hows, whats and whys to be answered. Yet, “It is almost inevitable”, according to Ireland and his peers, that robotics will become commonplace in the industry, at least in some parts of the construction process.

“Every traditional method began as an innovation at one point in time,” Ahmed says. “What we think of as novel or futuristic today soon becomes common-sense and practical tomorrow.”